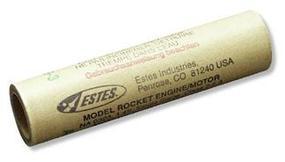

Ok. I must be honest here and state that this motor does exactly what it is supposed to do and does it very well. But.... Call it bias or whatever you want, I have been so conditioned to seeing that 24 mm motor case and thinking 'D', I just can't get used to the fact that this motor is only half of that. I have actually subconsciously reached for and pulled out an 18 mm motor, applied masking tape and started to put it in my scratch 24mm rocket when it does not even have an 18 mm motor mount.

But therein lies the biggest benefit to this motor. Unlike the 18 mm motors, if you had a 24mm bodytube, you were stuck with a D motor as a minimum unless you wanted to make an adaptor. And I find that with the lightweight body tubes, unless you want to permanently mount the 18mm mount, after pulling it out and inserting it a few times, the end of the bodytube gets a bit soft. And the crud that builds up around the inside of the tube makes inserting a 24mm motor afterwards all that much harder, as it can be tight when you insert it, but come loose just about the time the ejection charge kicks in.

With the 24mm 'C' motors, on windy days the total impulse of this motor is great as it goes high enough to look like a real rocket launch and the slight extra mass of larger case (Moves CG slightly backwards compare to an 18mm motor.), combined with the higher acceleration greatly aides in reducing weather cocking. In fact I will usually angle my rockets about 5 degrees down wind so they have a more vertical flight and still get them back. This really helps reduce stress at ejection on the recovery hardware as the velocity of the rocket at apogee is much lower.

Compared to a D, go down one delay setting on calm days. On windy days, if you launch vertical, keep with the same delay you would use for a windy day when flying a 'D' on a launch angled upwind from the vertical.